Problem 01. Invisibility of bolts.

5mm C-shaped brackets with integrated tapping, seamlessly inserted into square pipes and welded as the male component. The female counterpart featured a pipe with a tapered head bolt hole, guaranteeing flushness for optimal invisibility.

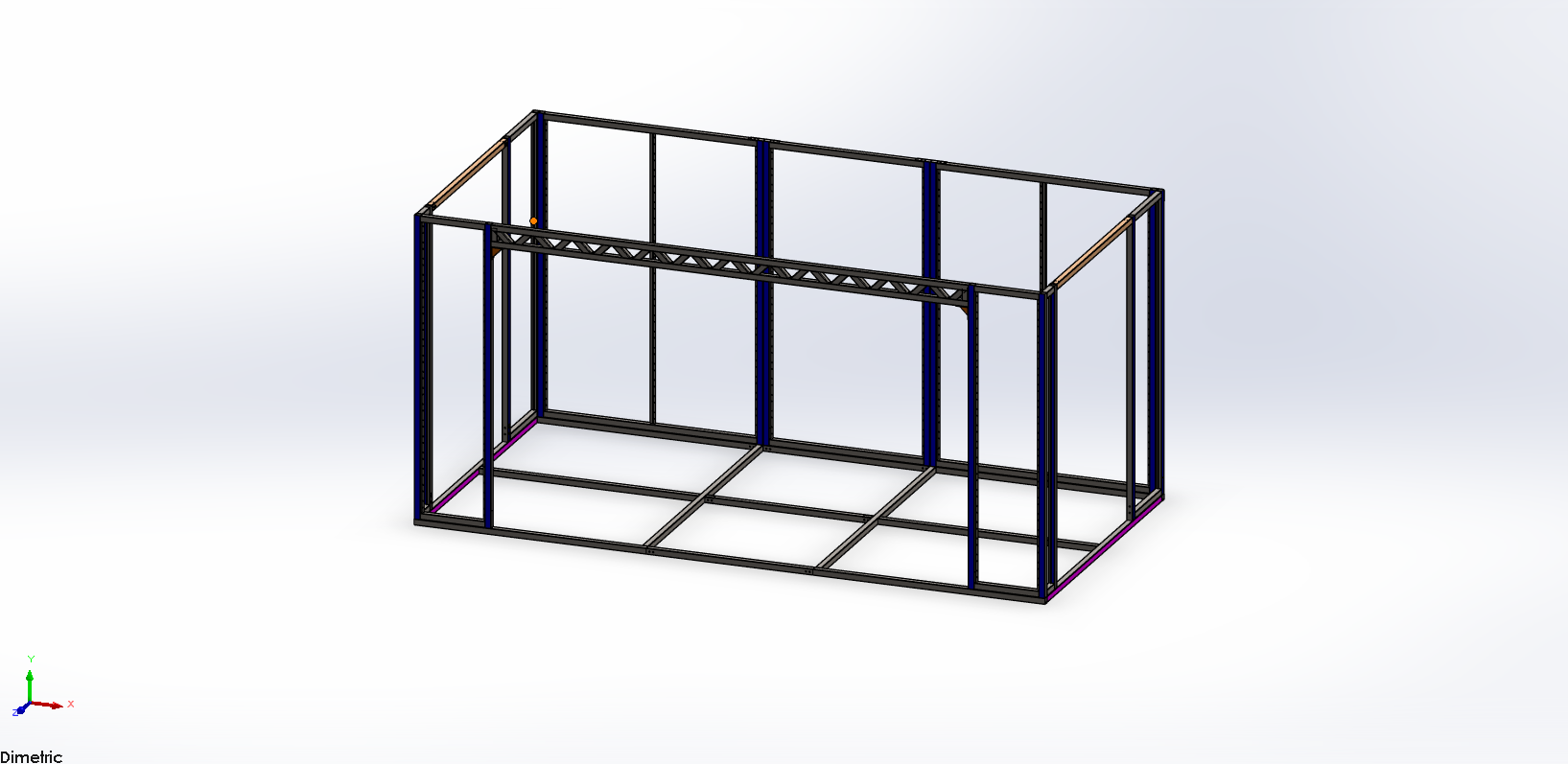

Problem 02. A weight distribution concern with the back section being 1.5 times heavier than the front.

Modified the front pipe’s thickness and reduced the back pipe’s thickness, ensuring optimal weight distribution and stability.

Problem 03. Timely delivery and high-quality results.

Collaborated closely with all vendors to ensure timely procurement of raw materials, as it was a high-priority project.