Problem 01. Uninterrupted and timely production.

Coordinated with powder coating and plating vendors to ensure quality work.

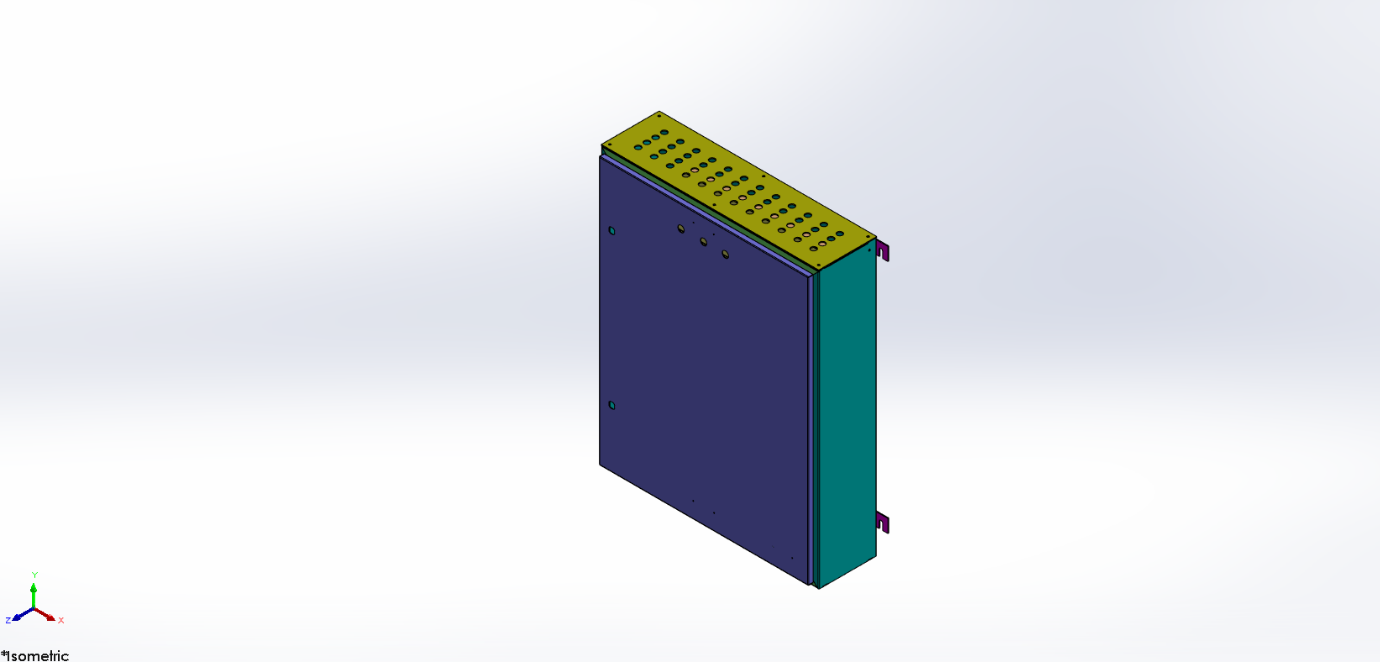

Problem 02. The challenge was overcoming material wastage to make these products cost-effective.

Implemented a process of punching separate panels to minimise sheet metal wastage and subsequently welding them together. Additionally, a locking system was introduced to streamline the welding process, eliminating the need for manual positioning by the welder.

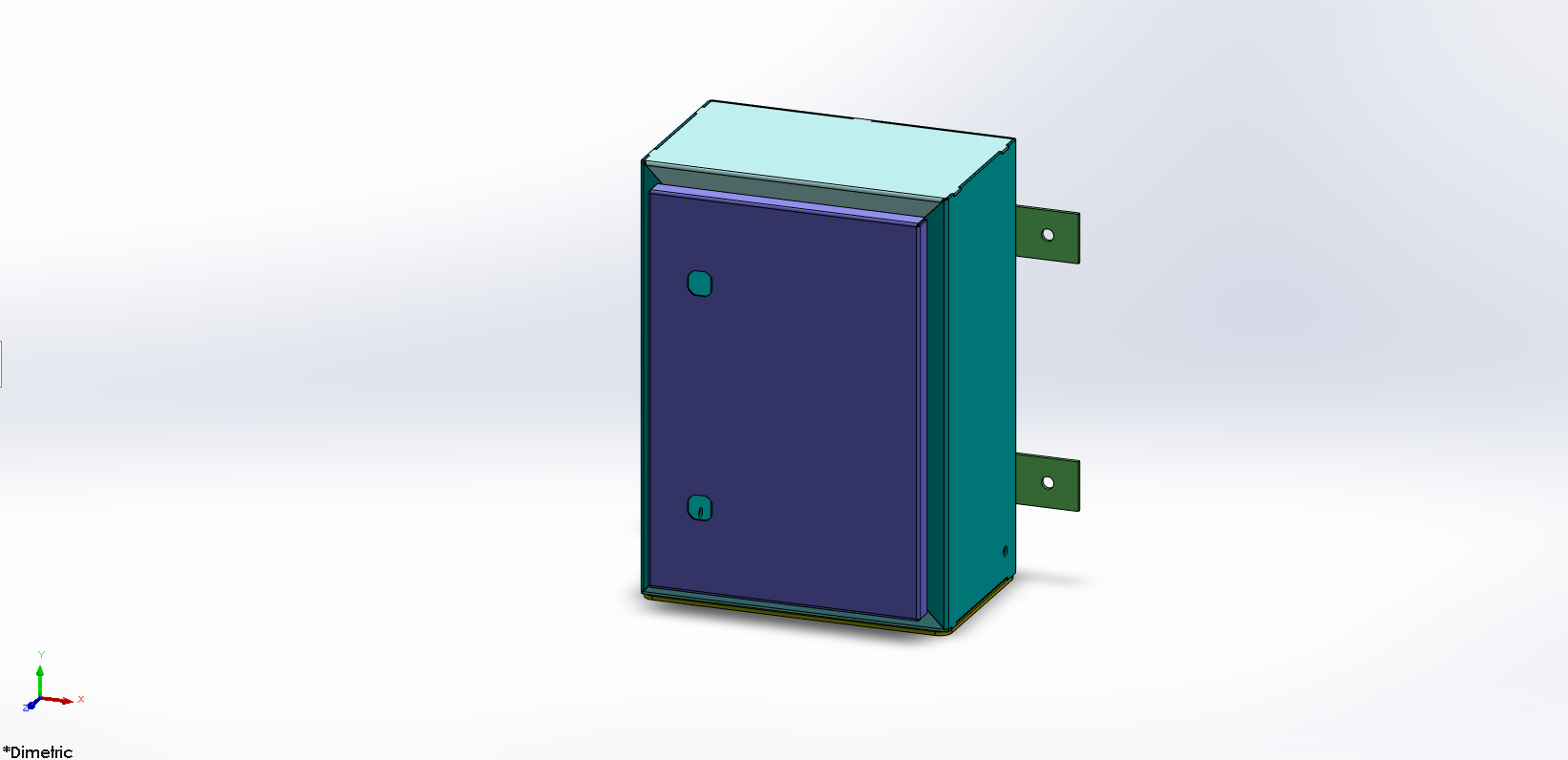

Problem 03. Positioning of the 3 mm Brackets.

To facilitate welding of the brackets onto the panel's rear, a 1.5 mm through hole was initially created, and a flush was later finished to simplify the welding process.