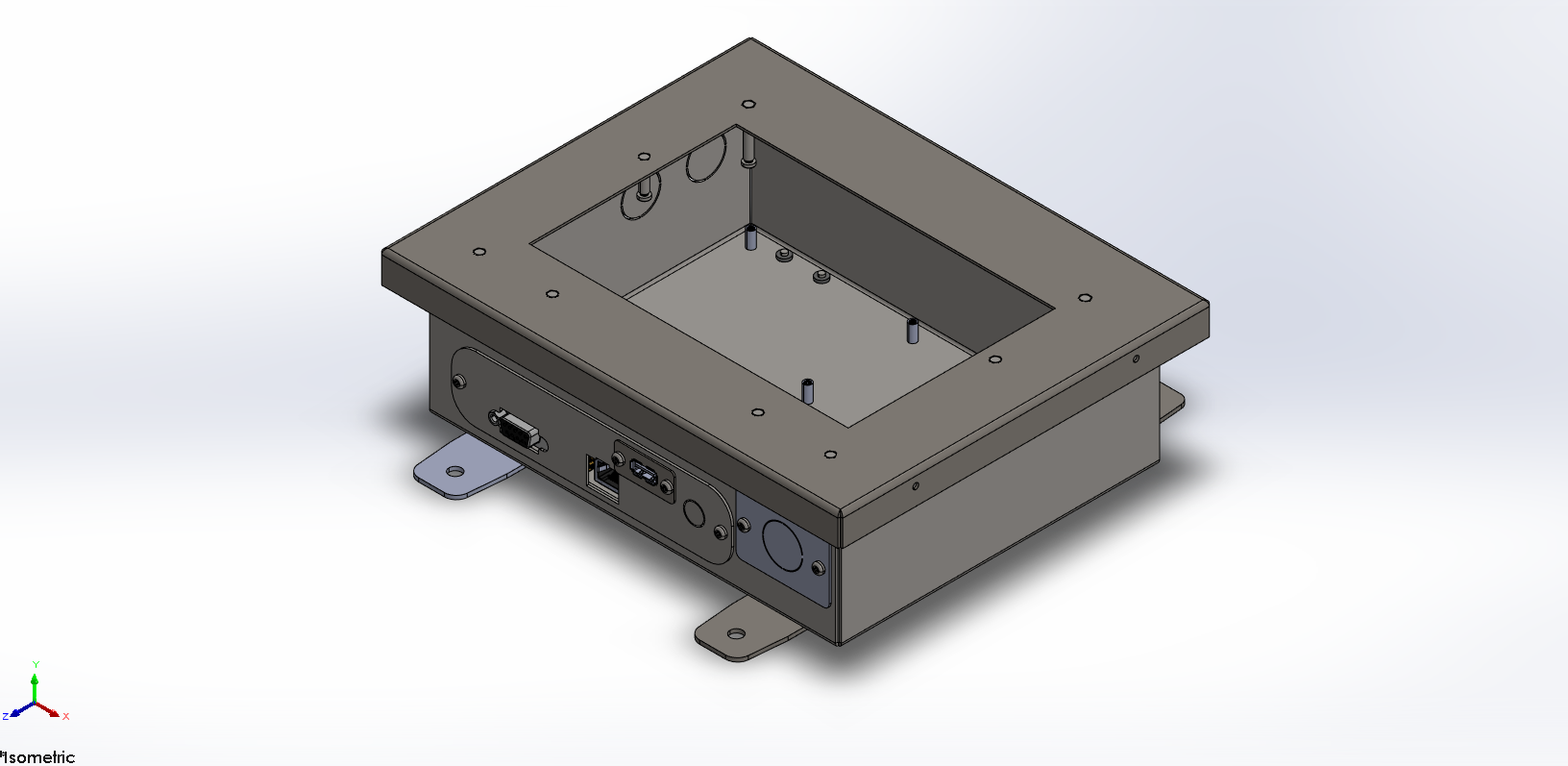

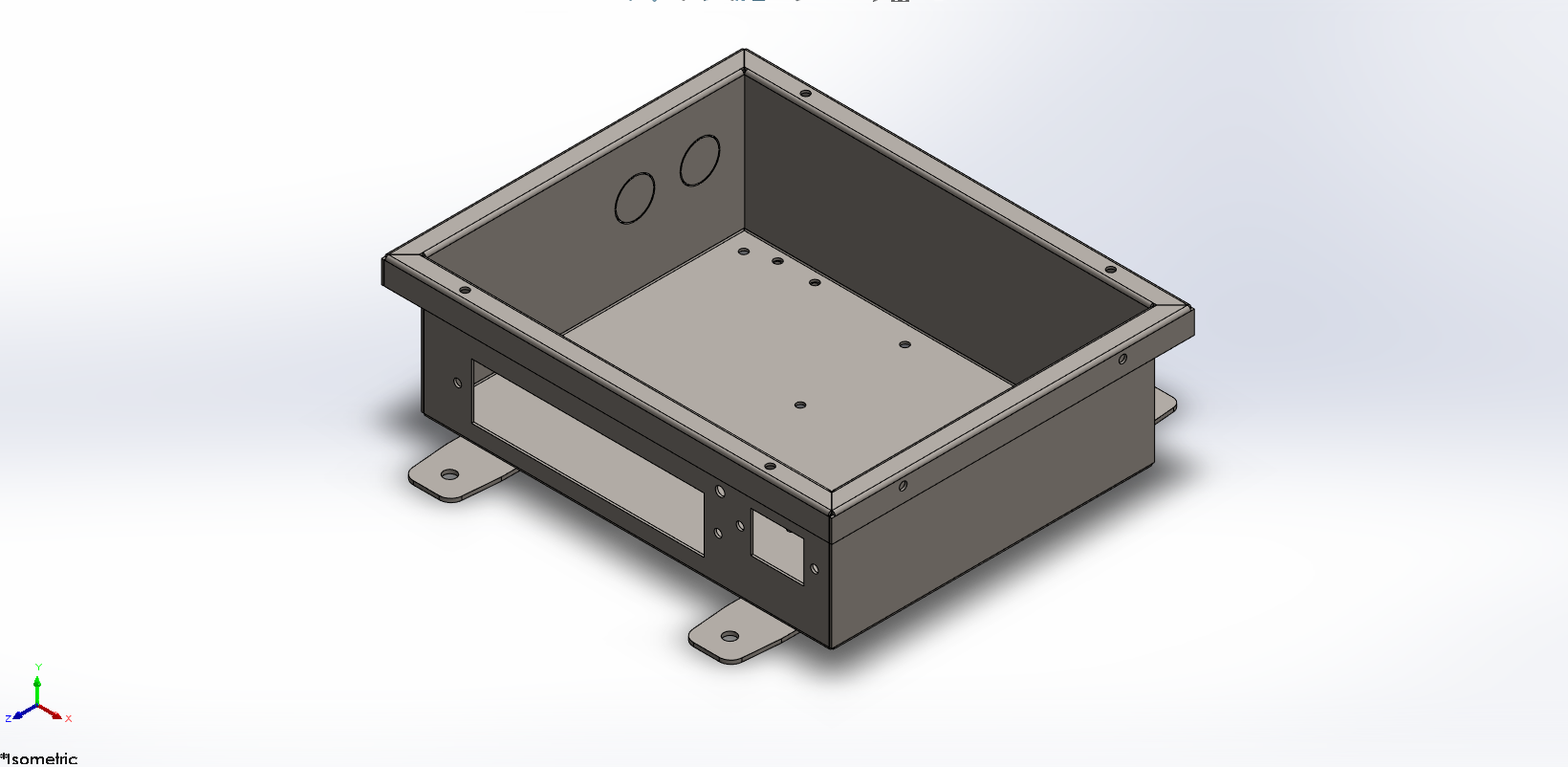

Problem 01. As per the client's specifications, laser cutting of the sheet was required to achieve precise dimensions.

Outsourcing was arranged, and actively engaged in discussions with a laser-cutting vendor, supplying them with the necessary materials to ensure the timely completion and delivery of the project.

Problem 02. The design provided by the client contained dimensional errors that were inadvertently overlooked, resulting in the commencement of production with the incorrect specifications. The mistake was only realised after the shipment had already been delivered to the client.

Separate production was initiated to rectify the issue, and adjustments were made to the production plan to guarantee minimal disruption to concurrent projects.

Problem 03. Upon receiving a lid design with revised dimensions from the client, we recognised the potential disruption to our established production plan.

To adapt efficiently, we replicated the new design precisely, incorporating additional thickness and a 0.2 mm tolerance to all sides during punching. Subsequently, drilled holes in all previously manufactured lids, rectified the discrepancy, and avoided unnecessary expenses and delays.